What is Induction Forging?

Induction forging is a heating process used to shape and form metal parts by applying heat into a metal billet through electromagnetic induction. It involves passing an alternating current through a coil, creating a magnetic field that induces eddy currents within the metal workpiece placed in the coil, causing it to heat rapidly. The heated metal is then forged into the desired shape using a press or hammer.

Benefits of Induction Forging

Efficient Heating: Induction forging uses electromagnetic energy to heat metals quickly and efficiently. Unlike other heating methods like gas furnaces or resistance heating, induction heating can provide much faster and more uniform heating, reducing the time and energy required to forge the metal.

Consistent Quality: Induction heating provides precise temperature control, resulting in consistent and repeatable quality of the forged parts. This is particularly important in industries that require high-quality, reliable parts, such as aerospace, automotive, and medical device manufacturing.

Reduced Scrap: Induction forging reduces scrap by minimizing heat distortion and material waste during the forging process. Induction heating can also eliminate the need for preheating or post-heating processes, which can further reduce scrap and improve efficiency and productivity.

Safe and Clean: Induction heating is a safe and environmentally clean process that minimizes the risks associated with open flames and toxic fumes from traditional heating methods. It also generates less noise pollution and reduces the need for air conditioning due to the low amount of heat emitted from the equipment.

Industries that use induction forging

Aerospace: Induction forging creates high-quality, durable components for aircraft engines, landing gears, and other critical aircraft parts.

Further reading:Hot Tack Testing for R&D: A Comprehensive Guide

Automotive: Induction forging is used to manufacture components for engines, transmissions, suspensions, and steering systems.

Energy: Induction forging is used to manufacture components for oil and gas drilling and production equipment and power generation equipment.

Medical: Induction forging creates precision components for medical devices such as orthopedic implants, pacemakers, and surgical instruments.

Mining: Induction forging is used to create components for mining equipment, such as drill bits, pumps, and conveyors.

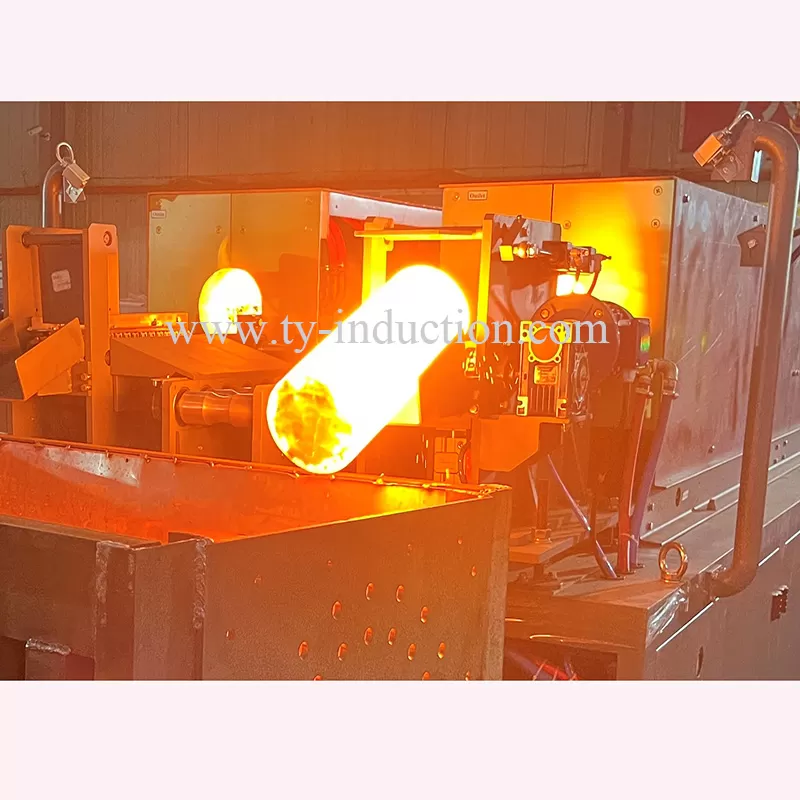

Innovative Technology of TY Forging Induction Heating Machine with Excellent Performance

The TY Induction Forge Heating Technology offers a comprehensive solution for heating a diverse range of bar and billet diameters. Equipped with fully automatic or semi-automatic material handling systems, water cooling systems, and temperature controls, it ensures efficient and precise heating processes. TY's induction power supply utilizes advanced IGBT technology and LC series resonant circuits, ensuring reliable performance even under varying load conditions. With the capability to start at 100% capacity and run continuously for 24 hours, it provides uninterrupted operation for demanding forging applications. Additionally, self-diagnostic features such as fault LEDs and alarm indicators contribute to the system's reliability and ease of maintenance. This innovative forging induction heating machine by TY is specifically designed to meet the rigorous demands of the forging industry, providing unparalleled efficiency and performance.

65

0

0

All Comments (0)

Previous: Hot Tack Testing for R&D: A Comprehensive Guide

Next: How Packing Machines Innovate Modern Manufacturing Processes?

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments